Techniques for addressing problems have become essential for success in the fast-paced, cutthroat business world of today. These cutting-edge solutions, which range from process optimization to improving customer experiences, enable companies to handle complexity, grasp opportunities, and maintain their lead in a world economy that is becoming more dynamic and interconnected by the day.

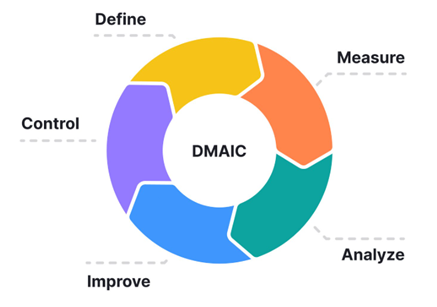

The DMAIC Model is one of these approaches to problem-solving that we shall discuss today. Six Sigma and other process improvement programs use this hierarchical model. We will go into great detail on this paradigm, including its benefits, drawbacks, and examples. Answers to some of the most common queries regarding the topic will also be displayed. Let’s go into the topic now.

What is meant by the DMAIC Model?

Six Sigma and other process improvement initiatives leverage the DMAIC model, which provides an organized approach to problem-solving.

The acronym for the five stages of the process is DMAIC, which stands for Define, Measure, Analyze, Improve, and Control. In order to improve quality, efficiency, and customer happiness, it assists businesses in locating, evaluating, and resolving process problems.

The DMAIC template

1. Define

The project’s objectives and scope are decided upon during the Define phase. This entails determining the issue or area in need of repair and establishing precise targets that complement corporate objectives and client demands. The development of a project charter that details the project’s goals, deliverables, stakeholders, scope, and schedule is a crucial step in this process. Teams are able to maintain focus and alignment throughout the process.

2. Measure

Data collection is the main goal of the Measure phase in order to comprehend the process. This entails determining process metrics and setting up a performance benchmark. Process observations, surveys, interviews, and the use of technology and measurement equipment are a few examples of data collection techniques. Quantifying the issue or area for improvement and provide a foundation for study are the objectives of this phase.

3. Analyze

To determine the underlying reasons of process problems or changes, the gathered data is examined during the Analyze phase. To find patterns, trends, and connections in the data, a variety of statistical and analytical methods are applied. Finding areas for improvement and gaining a better knowledge of the variables affecting process performance are the objectives.

4. Improve

Developing and putting into practice solutions to deal with the underlying issues found in the previous phase is the main goal of the Improve phase. Potential improvement ideas are generated and evaluated using creative problem-solving strategies. After solutions are chosen, their efficacy is evaluated through small-scale testing and implementation prior to full-scale deployment.

5. Control

Maintaining the gains made and avoiding the recurrence of issues are the goals of the control phase. Standard operating procedures, process controls, and monitoring systems are examples of control measures that are put in place to make sure the process stays stable and consistently achieves the intended performance goals. To guarantee long-term performance, regular reviews and ongoing monitoring are crucial.

Example of the DMAIC Model

Although it may appear complicated in principle, the DMAIC framework is actually rather straightforward. The corporate world is full of DMAIC examples. By making a DMAIC template, you may apply it to your own company. Let’s now examine a fictitious situation where the business ABC applies the DMAIC methodology and achieves favorable outcomes.

ABC Company

The DMAIC approach is used by manufacturing company ABC Company to improve the productivity of their production process for Product A. After experiencing high failure rates and client complaints at first, the business identifies the issue, calculates defect rates, and investigates the underlying causes, such as problems with machine calibration and the quality of the raw materials.

The ANC firm obtains notable decreases in defect rates through the implementation of innovations including machinery recalibration and improved quality control methods, which results in better product quality, less rework, and more profitability. ABC Company methodically found and fixed the process inefficiencies by using the structured approach of DMAIC. Its operating performance increased.

Pros and Cons of Using the DMAIC Model

DMAIC is used to guarantee continual improvement and enhance procedures. In order to maximize the model’s success, firms should be aware of any potential drawbacks and problems, even though it offers many advantages and benefits in terms of systematic problem-solving and continuous improvement. Nevertheless, let’s examine the benefits and drawbacks:

Benefits

There is more to the DMAIC paradigm than merely a structure. It is a driving force behind organizational change. It empowers organizations and provides numerous benefits by offering a well-organized roadmap. Let’s examine a few benefits and see how it increases competition:

Structured approach

Teams are guided through a structured issue-solving process from problem identification to solution implementation by the DMAIC model, which offers a systematic framework with defined stages (Define, Measure, Analyze, Improve, Control).

Data-driven decisions

It places a strong emphasis on gathering and analyzing pertinent data in order to comprehend process performance, pinpoint the underlying causes of issues, and help team members make defensible judgments rather than speculative ones.

Customer focus

Putting the customer's voice first guarantees that process enhancements meet their needs and expectations, which eventually increases customer loyalty and satisfaction..

Continuous improvement culture

By encouraging teams to examine and improve processes on a regular basis, the DMAIC framework helps organizations develop a culture of continuous improvement that leads to gradual improvements and long-term, sustainable performance increases.

Cross-functional collaboration

It encourages cooperation between various stakeholders, including as frontline staff, subject matter experts, and process owners, fostering shared accountability and teamwork for projects aimed at improving and solving problems.

Drawbacks

The DMAIC approach may provide difficulties for certain firms, despite its many benefits for process optimization and quality enhancement. Notwithstanding its methodical approach, certain elements, like limited resources and opposition to change, may compromise its efficacy. Let’s examine some possible drawbacks:

Time and resource-intensive

Teams with limited capacity or financial constraints may have difficulties while implementing DMAIC because it can take a lot of time, money, and resources, especially for large-scale projects or businesses with complicated processes.

Rigidity and complexity

Especially for smaller projects or teams with little expertise with process improvement techniques, the organized character of DMAIC may be viewed as unduly complex and rigid, which could cause resistance or make application challenging..

Resistance to change

Workers may oppose DMAIC's modifications, especially if they believe they will interfere with long-standing procedures or if they don't support or comprehend the advantages of process improvement projects

Lack of flexibility

The sequential method and predetermined steps of the DMAIC paradigm may not be flexible enough to adapt to dynamic or quickly changing contexts, where agile or iterative problem-solving techniques may be more appropriate..

Overemphasis on analysis

In DMAIC, an overemphasis on data analysts and measurement can result in analysis paralysis, a condition in which teams prioritize data collecting and analysis over action and implementation, which slows down progress and reduces the efficacy of improvement initiatives.

Conclusions

To sum up, the DMAIC Model is a useful instrument for raising quality. This five-step approach can be used by businesses to promote innovative problem-solving. We’ve seen a thorough explanation, an example, and the model’s benefits and drawbacks. You can begin putting it into practice in your own company and observe the results!

A well-crafted and insightful piece by Mr. Viraj Prakash! The explanation of the DMAIC Model is both comprehensive and practical, making it easy for readers to understand and apply. The use of a real-world example adds great clarity to the concept. Mr. Prakash’s balanced view—highlighting both benefits and challenges—demonstrates deep expertise in process improvement. His structured approach and emphasis on continuous improvement make this a valuable resource for professionals. Excellent contribution to the field of project and delivery management.

Thanks and regards

HARRISH

Thank u bro..